Subperiosteal implants

Subperiosteal Implants for the treatment of large maxillary atrophies

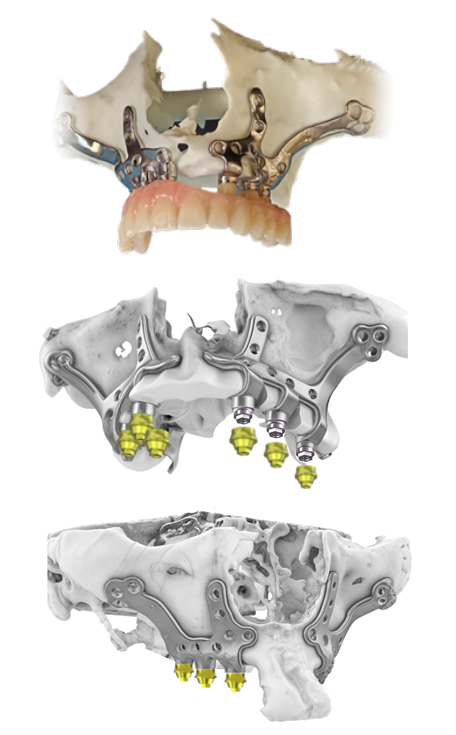

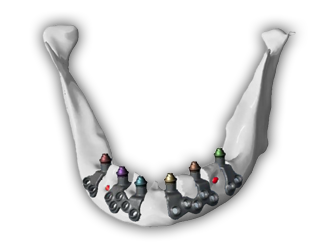

A multidisciplinary team composed of engineers, maxillofacial surgeons and dental technicians are responsible for planning, designing and manufacturing a customized structure/framework from the helical CT or clinic Cone Beam. This structure, manufactured in Ti-6Al-4V and laser sintered, is the one that will support the implants strategically planned to support the patient´s future prostheses.

The framework has a controlled thickness of 0.8mm in all its area that maximizes the stability and protection of the soft tissue. This provides immediate and long-term esthetic and functional results.

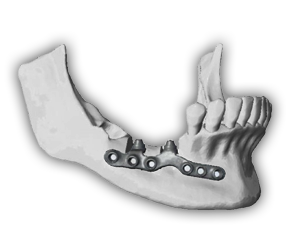

Engineers will perform a finite element study of the subperiosteal structure and provisional prosthesis to ensure proper load distribution.

You can choose the option of using yellow nitrided Multi-unit abutments that integrate better with soft tissues. These are screwed to the framework, which allows you to choose their shoulder height or to change them in case of screw breakage or change in gingival thickness.

The prosthodontist can choose between ordering the immediate prosthesis for the same day of surgery or taking an impression at the clinic and producing it with the local laboratory.

Fully digitalized process: from the intraoral scans, dental CT scan and patient registration, it is performed in an easy and fast platform, which will allow the design and fabrication of the subperiosteal framework.

Advantages of Southern Implants subperiosteal Implants:

• Yellow nitrided Multi-Unit abutments, removable in case of screw breakage or tissue thickness variation.

• Helical CT (hospital) or Cone Beam (clinic) thanks to the use of post-processing with artificial intelligence.

• Titanium Grade 23 (Ti-6Al-4V) laser sintered framework increasing the structure strength and biocompatibility with hard tissues.

• Guaranteed framework thickness of 0.8mm to facilitate soft tissue protection.

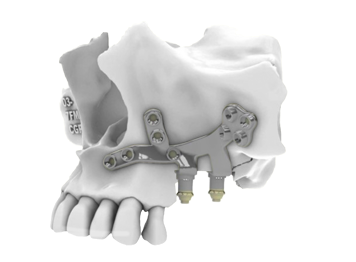

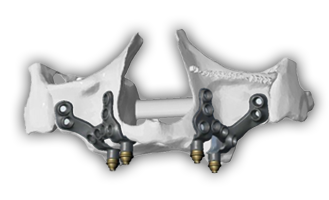

• Full arch treatments with independent frameworks per quadrant.

Technical features:

• Extensive experience of Kune Implants nationally and internationally with more than 250 subperiosteal implant treatments per year.

• Specific planning software for technologically advanced subperiosteal treatments, Rhino Medical.

• Finite element study of the structure and the provisional prostheses.

Full arch, 2 sections, 6 implants, external connections + Multi-unit abutments

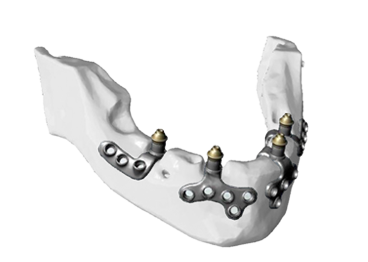

Partial, 1 section, 12 implants, external connections + Multi-unit abutments

Full arch, 4 sections, 4 implants, external connections + Multi-unit abutments

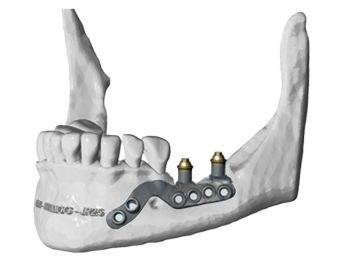

Partial, 1 section, 2 implants, external connections + Multi-unit abutments

Prosthodontist options

• Choice between Implants with Multi-unit connections or external connections with removable Multi-unit abutments.

• PMMA provisional prostheses on the day of surgery or take a conventional impression after surgery. A positioning guide ensures the correct positioning of the two structures in the maxilla so that the provisional restoration has a passive fit.

Pack subperiosteal implants

• Conversion of doublé CT Cone Beam (clinic) o helical (hospital).

• Design and planning of the subperiosteal frameworks by engineers specialized in craniofacial and maxilofacial medicine.

• Sending of the planning by e-mail.

• Review and modification in remote control with the engineers.

• Creation of the surgical report.

• Fabrication and shipment of the subperiosteal Implants, cutting guide and positioning guide if necessary.

• Delivery to the clinic of all the surgical material, osteosynthesis screws, rescue screw, screwdriver tips, handle and osteosynthesis drills.

Pack provisional

• Provisional restoration in PMMA with interfaces and screws.

Video demonstration of the design and planning of subperiosteal Implants

Kune Implants team of engineers, specialists in craniofacial and maxilofacial treatments and specifically trained by advanced subperiosteal implant professionals with extensive experience and treatments, plan and design the frameworks in the planning software once all the patient´s digital files have been received.

Subperiosteal implant surgery

An expert maxillofacial surgeon performs the surgery with technical support from the chief engineer who planned the treatment, explaining key tips and secrets for safe and accurate surgery.

9 videos showing each phase of the surgery.

Workflow

STEP 1. PERFORMING THE CT SCAN

CT scan patient with diagnostic wax-up and CT scan only the diagnostic wax-up (Double CT technique) or a CT of the patient with a mouth-opener

Plan a minimum of 21 days (15 working days) from the moment you register the treatment and upload the digital files, until the subperiosteal implants arrive at the clinic

STEP 2. PLANNING REVIEW

Review of the planning suggested by the engineers

STEP 3. FABRICATION AND SHIPMENT

Fabrication and shipment to the clinic of the subperiosteal Implants and all the surgical and prosthodontic material

Full arch, 2 sections. 4 implants, external connections + Multi-unit abutments

Partial, 1 section, 2 implants, external connections

Partial, 1 section, 1 implant, external connections

Partial, 1 section, 2 implants, external connections

Full arch, 4 sections, 6 implants, external connections + Multi-unit abutments

Full arch, 1 section, 4 implants, Multi-unit connections

Partial oncological, 1 section, 3 implants, external connections + Multi-unit abutments

Partial, 1 section, 2 implants, Multi-unit connections

Subperiosteal implants

A multidisciplinary team plans, designs and manufactures the customized framework for the realization of the subperiosteal implant treatment. Its individualized design maximizes stability and facilitates bone regeneration, providing immediate esthetic and functional results.